Smarter batteries, powered by their own data

With Zenfinity’s Digital Twin Platform, every battery becomes a live data source — from first deployment to recycling. By understanding what’s happening inside each cell in real time, we can refine design, extend life, and unlock better performance for every customer.

Zenfinity Digital Twin

The brain behind every Zenfinity battery

From the moment a pack starts being manufactured in the factory, it begins generating a continuous stream of data: temperatures, currents, voltages, charge–discharge patterns, locations, and events in the field.

Our Digital Twin captures and learns from this data, creating a virtual replica of every battery system. This lets us:

- Design packs around real duty cycles, not lab guesses

- Continuously improve performance, safety, and lifetime

- Turn batteries from “black boxes” into transparent, manageable assets

Through data, we’re building more reliable, safer, and more sustainable battery systems for fleets, OEMs, and energy customers

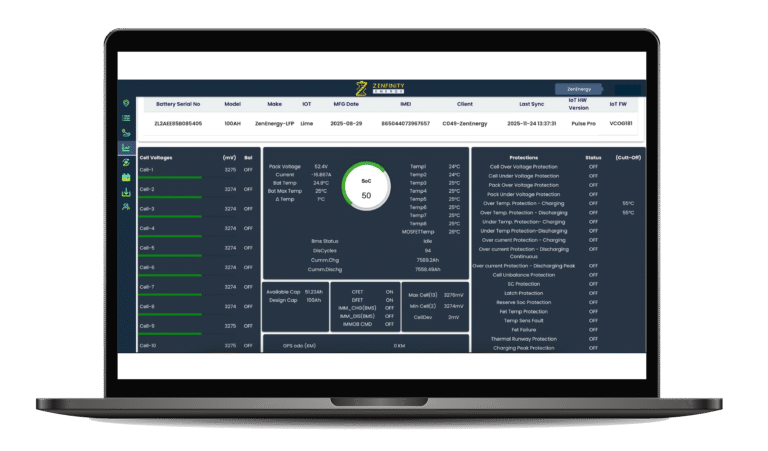

Keep your batteries working, not waiting

Battery fleet management – maximizing uptime

A live view of your entire battery fleet — across vehicles, sites, or storage systems — helps operators act before a minor anomaly becomes a costly shutdown.

- Real-time monitoring of key parameters and alarms

- Pack- and site-level dashboards tailored to EV fleets and energy storage

- Insights that reduce unplanned downtime and keep assets earning

Remote diagnostics – fewer site visits, faster resolutions

Instead of sending specialists to inspect a pack, engineers can diagnose issues remotely using data from the Digital Twin.

- Drill down to cell, string, or module level from anywhere

- Faster troubleshooting and root-cause analysis

- Lower dependence on scarce on-ground battery experts

Anomaly detection – catching problems early

Machine-learning driven anomaly detection identifies unusual behavior long before it becomes a failure.

- Spot potential defects or misuse patterns early

- Contain field issues and reduce the risk of large-scale recalls

- Protect both brand trust and operating margins

Improve performance without touching the hardware

Over-the-air updates – performance at the speed of software

Battery behavior is heavily influenced by software — control algorithms, limits, protections. With Zenfinity:

- Deployed batteries receive over-the-air (OTA) firmware and configuration updates

- New learnings from the field can be rolled out fleet-wide in one go

- Packs get smarter and more efficient over time, without physical upgrades

One-click system checks – instant health snapshots

Operators can trigger a full self-test of a battery system from the dashboard.

- Automated test routines run in the background

- Detailed event logs and reports highlight what needs attention

- Shortens the time from issue to action

Seeing ageing before it shows up on the road

High-resolution telemetry – the foundation for better cells

Zenfinity’s Digital Twin captures rich telemetry at the cell and pack level.

- High-frequency data from real routes, climates, and loads

- Insights into how different chemistries behave in Indian conditions

- Feedback loop from field back to cell R&D and pack design

Predictive health models – planning replacements, not reacting to failures

By combining telemetry with advanced models, we can forecast how a pack will age.

- State-of-health estimation at cell and pack level

- Remaining useful life predictions for each asset

- Smarter decisions on rotation, refurbishment, or replacement

Enabling confident warranties & service models

When battery usage and health are clearly understood:

- Warranties can be structured around data-backed performance

- Service contracts and BaaS models become easier to price and manage

- Risk is reduced for both Zenfinity and our customers

Enterprise-grade protection for critical energy assets

Secure cloud infrastructure

Zenfinity’s Digital Twin is hosted on industry-standard, security-hardened cloud infrastructure, aligned with modern data protection and cyber security practices.

- Encrypted communication between batteries, gateways, and cloud

- Robust backup and disaster recovery mechanisms

- Auditable logs for compliance and investigations

Fine-grained access management

Different stakeholders need different levels of visibility.

- Role-based, multi-tenant access control

- Separate views for OEMs, fleet operators, service partners, and internal teams

- Strict permissioning so sensitive data only reaches the right eyes

From first life to second life to recycling

Full lifecycle visibility – from deployment to retirement

With Digital Twin data, we know how each battery has lived its life:

- Duty cycles, operating conditions, and stress events

- True health at the end of first life

- Suitability for second-life applications or direct recycling

Enabling buy-back & recycling programs

This transparency allows Zenfinity and its partners to:

- Structure buy-back offers tied to verified usage and health history

- Channel suitable packs into second-life stationary storage

- Route end-of-life batteries to responsible recyclers with full traceability